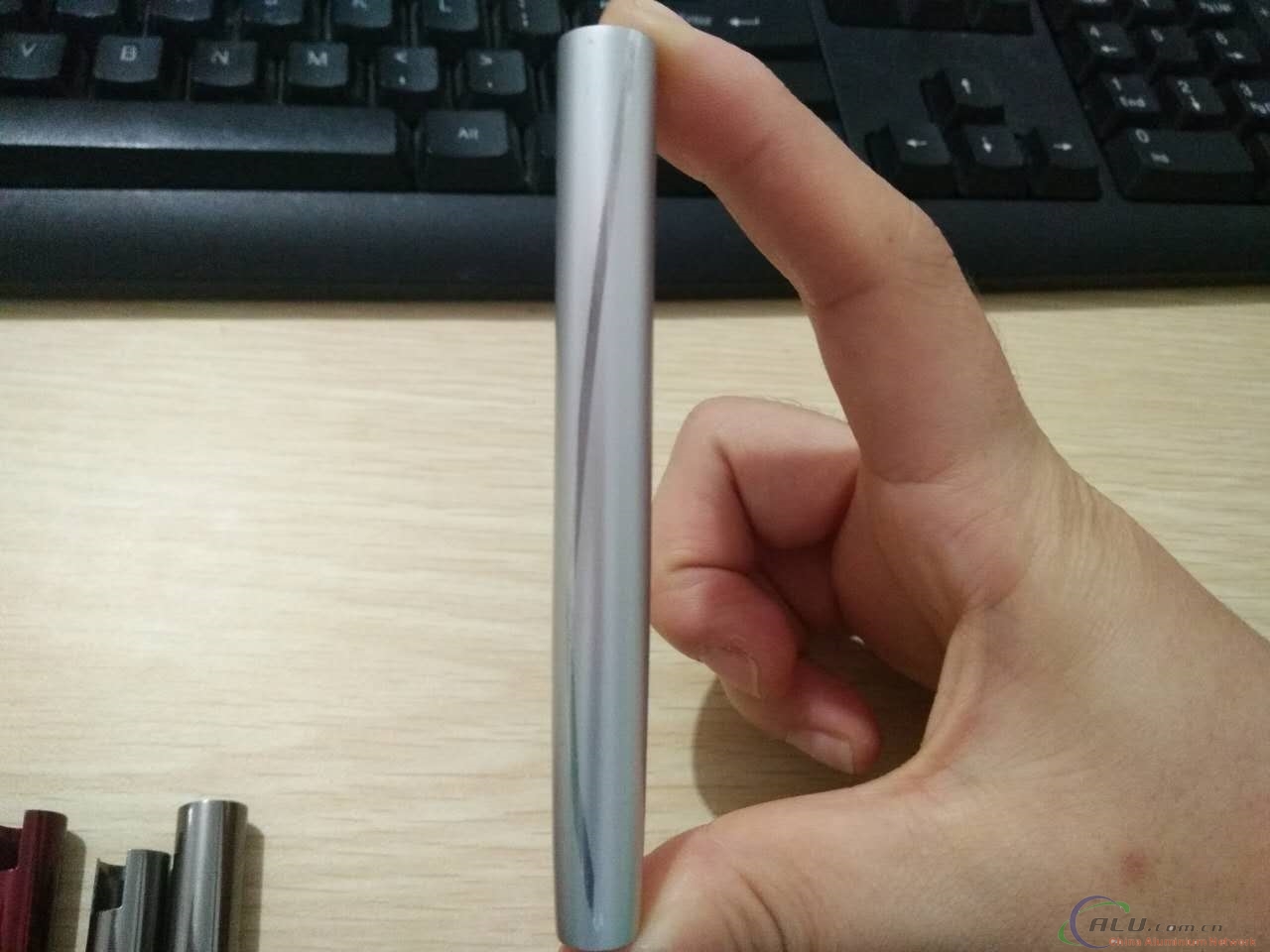

Two color Anodizing Aluminum Extrusion Products with small size

- Free Member

- Jiangyin Joyda Aluminum Co.,Ltd(SAPA jiangyin)

- Tel:+86 13921958849

- Fax:

- Add:No.888 Shiji Avenue(s),Zhouzhuang Town,Jiangyin,Jiangsu Province,China

- Post Code::214423

- E-mail:yuki@xinyu-aluminum.com

Details

ANODIZING:Conventional Sulfuric Acid Anodizing of Aluminum Parts

Anodizing is the electrochemical oxidation of an aluminum surface designed to produce a stable film of the aluminums oxide on that surface. This transparent anodic coating is a microscopic cellular structure composed of pores that can be impregnated with aqueous dyes to achieve a colored anodized aluminum finish. In addition to being extremely hard and resistant to abrasion, the anodic coating converts the aluminum surface to a non-conductive surface. For customers with specific applications that require grounding or the maintenance of a conductive area, we offer a variety of masking services.

ALODINING: Iriditing-Chrome Conversion Coating

Alodining (chemical conversion) is a coating method intended to provide corrosion prevention to aluminum products left unpainted, as well as to improve adhesion of painting processes. While not designed to be a cosmetic or decorative coating, we take great pride in producing alodined parts with minimal to no unappealing streaks or water spots. Unlike anodizing, aluminum parts are alodined in only two colors, clear and gold. Unless specified, gold alodining is the standard and offers the most corrosion protection.

Other biz of this company

Inquire Now

- Subject:

- Subject Must Input!

- Message:

- Message Must Input!

- Verification Code:

Your Contact Information:

- Company Name:

- Country:

- *

- Contact Person:

- *

- E-mail:

- *

- Telephone No.:

- *

- Address:

- Fax:

- Website:

-

If you want to send the message without registration, please fill the above contact

information to this supplier.

If you want to send the message without registration, please fill the above contact

information to this supplier.